NIDECO

Norwegian International Development Company AS

913157427MVA

Plant structure

Steel mould

System Requirements

Family Size Rural Biogas System

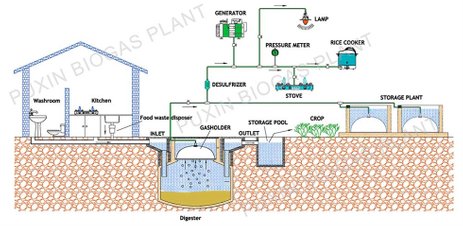

This family biogas digester is mainly for farmhouses or domestic houses, and it has three main functions: 1) to treat wastes that could otherwise attract flies and cause diseases (livestock waste, human sewage and food wastes), 2) to get biogas for cooking without smoke, lighting and electricity, and 3) fertilizer for increased growth of crops.

It is composed of a 6 or 10 m3 biogas digester (tank), pipes, gas purification unit and a gas tank. Different devices are available, such as cooking stove, lamp, rice cooker and generator for producing power.

The main components of the storage system are the concrete tank and glass fibre reinforced plastic gasholder. The working principle of the storage tanks is performed by pressure, produced by water inside of the tank. There are three pipes in the digester, the in- and outlet and gas pipe. The inlet pipe is a pipe where the feedstock is added and the outlet is provided for the automatic discharge of liquid fertilizer. The gas pipe provides you biogas.

For this biogas plant there are different fermentation materials allowed. This plant can use fluidities (e.g. animal or human) wastes and solids (e.g. straw, grass).

The amounts of gas produced, depend on the type and amounts of feedstock. To produce 10 m3 biogas, the plant needs e.g. 115 kg pig manure or 150 kg cow manure.

The biogas system can last more than 30 years, hereunder the replaceable glass fibre reinforced plastic gasholder that can last for more than 10 years.

Technical specifications

Airtight tank

Solid organic material (straw and grass, waste etc.) can be used

Easy to maintain

The biogas system can last over 30 years

Excellent safety feature

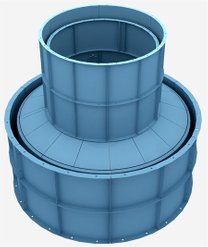

The biogas plant composed of a concrete digester that is built with a steel mould, a glass fibre reinforced, plastic gas-holder and a concrete or glass fibre reinforced plastic cover

Dimensions: the digester is 6 or 10 m3 capacity; the gasholder is 1.6 m of diameter, 0.6 m of height and 1 m3 capacity

Contact your nearest NIDECO representative for further details and prices.

Brief introduction to the technology

Download the NIDECO Flyer